Customer Services

Copyright © 2025 Desertcart Holdings Limited

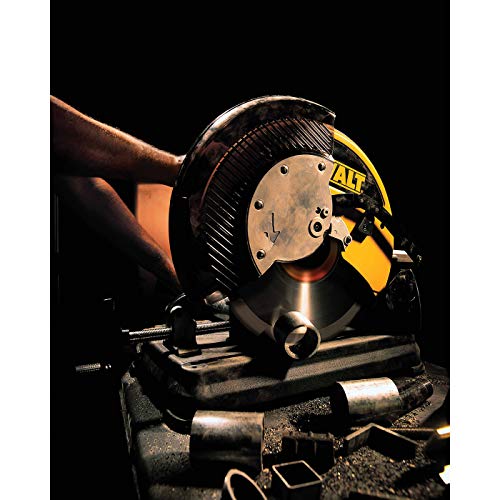

⚡ Cut Clean, Cut Strong — Own the Metal Game!

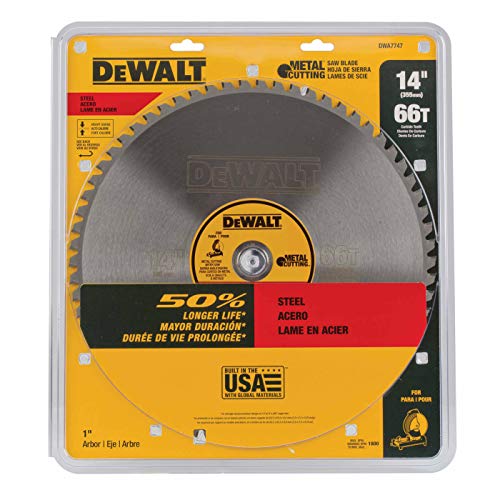

The DeWalt DWA7747 14" 66-tooth heavy-gauge saw blade is engineered with 12% titanium carbide and tri-foil braze technology to deliver precise, burr-free cuts on ferrous metals. Featuring expansion slots for heat dissipation and a stiff plate design to minimize run-out, this blade offers exceptional durability and longevity, capable of over 1,200 cuts at 1800 RPM. Perfect for professional metalworkers seeking clean, efficient, and reliable performance.

| ASIN | B0000302QT |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #97,155 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #246 in Circular Saw Blades |

| Brand | DEWALT |

| Color | Multi |

| Customer Reviews | 4.5 4.5 out of 5 stars (389) |

| Date First Available | April 5, 2004 |

| Finish | Brushed |

| Global Trade Identification Number | 00028874077478 |

| Included Components | DWA7747 - 14IN 66 Tooth Metal Cutting Blade with 1IN Arbor |

| Is Discontinued By Manufacturer | No |

| Item Package Quantity | 1 |

| Item Weight | 4.2 ounces |

| Item model number | DWA7747 |

| Manufacturer | DEWALT |

| Material | Titanium Carbide |

| Number Of Pieces | 1 |

| Number of Teeth | 66 |

| Part Number | DWA7747 |

| Pattern | Solid |

| Power Source | Hand Powered |

| Product Dimensions | 14"L x 14"W |

| Shape | Rectangular |

| Size | 14-Inch |

| Style | 66-Tooth |

| UPC | 028874077478 |

| Voltage | 120 |

S**K

Better than a Ginsu knife

I have a small fab shop and we use this daily for cutting everything from 1" square steel tube .100 wall all the way up to 5"x 3" .250 wall steel tube, 1/8",3/16",1/4"and 3/8" x up to 4" angle as well as aluminum extrusions 1",2",3" square aluminum tube (a little wd40 on the blade while cutting aluminum helps keep the teeth clear) and I usually get a couple of months out of the blade before it needs sharpening, I've gotten the same blade sharpened a few times before it needed retirement, usually due to lost teeth. I have four of these blades and cycle them, when they get dull I switch it out and send it out for sharpening. I haven't kept count of how many cuts we're getting but I would guess at least a thousand as long as the material is clamped properly and supported when cutting long pieces, if the work piece moves while you're cutting it will remove teeth in a hurry ruining the blade. I've got an abrasive blade chop saw and it hasn't been used in years other than to cut hardened shaft like thomson or superior shaft since I bought the Dewalt dw872 that uses this blade, it makes cuts cleaner, faster and more square than the abrasive blade ever could, without all the dust! Also a word of caution you can't use this blade on an abrasive blade machine because the wheel speed is too high, and don't use it on hardened shaft or you'll get a very short life out if it speaking from expensive experience.

D**E

Very Good Metal Cutting Blade

Theses blades are incredible and when used properly work as good as any fine wood chop or miter saw. No one get's to use it that is not trained on how to. Cost is not prohibitive to the untrained. Still going strong after several jobs.

J**T

Heavy duty blade, long lasting, great cuts.

I probably made 500+ cuts with this blade in 1/4" steel angle, and square tubing before it finally started getting dull. I even cut quite a bit of heavy aluminum stock also with really good results. I was so happy with the performance I bought another identical blade and sent the old one to be sharpened. If you don't bear down and let the blade do the work you will get lots and lots of clean straight cuts.

J**.

Replacement for the DW872 saw

DO NOT INSTALL THIS BLADE IN A PORTER CABLE MACHINE. It will turn too fast and you will be one of the morons complaining about the short life of the Dewalt blade. I bought this as a backup for the DW872 saw from Dewalt. Remember that it has to turn much slower than most all abrasive saws turn, and turning it faster will just shorten its life, and possibly your own. This means that turning the bladed faster than 1300 RPM can be very dangerous, and the danger is all in relation to how much faster you turn it, and what you cut with it. Even the saw it is made for, which runs at the correct speed, must be used properly to prevent damage to the blade, to the work, and to the user. Never rush the cut, the slower you go, the less heat and damage to the blade you will get. I cut angle iron, like bed frame material with ease. It cuts aluminum fast an easy. Always run the blade no faster than the specifications say to run it. The least you will do is ruin the blade, the most you will do is ruin your life.

L**H

Clean cuts on square tubing and profiles @ 1800 RPM

There are limits to the linear velocity at which metal can be cut with a mechanical blade that has teeth, without lubrication. So the 1800 RPM is absolutely no surprise. A dry metal saw is always a compromise, because of friction and heat issues. In my case, a speed controller for my saw solved the 1800 RPM issue. This blade can turn your miter saw into a very precise metal cutting tool, with no cleanup necessary for further welding or riveting. I have used it mostly on 18-22 Gauge stock (That is: 1.2 to 0.76 mm), and at this material thickness it is just absolutely NICE with fast and precise cuts. Heavy 1/8 inch (3.17 mm) round or angled material is possible. I found that this blade cuts this thickness much faster and cleaner than an abrasive chop-off disk, but also wears down the blade much faster, compared to thinner stock. Anything thicker is better done with a plasma cutter or another tool. I have just worn down my first blade, and I will get another one while the first is going to be resharpened. The mileage I got out of this blade is OK given the heavy gauge I was cutting. Diligently used with care, and in the range of 0.8 to 1.5mm material thickness: Great results, clean and precise cuts. I would not recommend it for anything heavier than 2 mm mild steel.

M**S

Great quality

It might be a little more money, but it lasts 3x longer than the others.

T**E

P.O.S.

I have owned my dewalt saw for 6 years and the original blade gave up in June 2020 so I ordered this new blade and it was delivered on 6/10/20 and I have only used it lightly on about 50 cuts with a wall thickness of only 3/16" max and not even 2 months today 8/5/20 the blade is so dull it wont even give a spark like it is even trying to cut, I dont force the saw I put lite pressure on the saw and let the blade do its job but this blade is so dull its trash, I wish I could return it but dont know exactly how to do that, I believe they sent me a refurbished resharpened blade. this blade should have lasted around 1000 cuts. I did get a hold of amazon and they are sending me a new blade and its suppose to get here today 8/7/20 I just hope the new blade holds up but cudos for amazons customer service they were great. but guess what now that I have canceled my prime account they dont seem to want to get it to me it was due 8/7/20 and their saying if I dont get it by 8/10/20 I can contact them for another replacement or a refund, well I asked for a refund but they wouldnt give me one, am I going to get this or are they just hoping I will just fade away. ???????. Dont do prime they dont hold up to their end of the deal.

F**.

Good blade!!

This is an overall good blade. We chop some steel and a lot of aluminum. This is the same blade that came on the saw. Since we chop a lot of aluminum we purchased aluminum specific blades. This blade is much better on aluminum than those were. Their shipping was excellent.

C**N

Necesito hacer más cortes para dar mi opinión. A ver si da los 1500 cortes que dice poder hacer antes de tener que reemplazarlo. Lo que no dice es el promedio del grosor de los cortes y la velocidad de corte antes de considerar que necesita remplazo.

S**K

I have a small fab shop and we use this daily for cutting everything from 1" square steel tube .100 wall all the way up to 5"x 3" .250 wall steel tube, 1/8",3/16",1/4"and 3/8" x up to 4" angle as well as aluminum extrusions 1",2",3" square aluminum tube (a little wd40 on the blade while cutting aluminum helps keep the teeth clear) and I usually get a couple of months out of the blade before it needs sharpening, I've gotten the same blade sharpened a few times before it needed retirement, usually due to lost teeth. I have four of these blades and cycle them, when they get dull I switch it out and send it out for sharpening. I haven't kept count of how many cuts we're getting but I would guess at least a thousand as long as the material is clamped properly and supported when cutting long pieces, if the work piece moves while you're cutting it will remove teeth in a hurry ruining the blade. I've got an abrasive blade chop saw and it hasn't been used in years other than to cut hardened shaft like thomson or superior shaft since I bought the Dewalt dw872 that uses this blade, it makes cuts cleaner, faster and more square than the abrasive blade ever could, without all the dust! Also a word of caution you can't use this blade on an abrasive blade machine because the wheel speed is too high, and don't use it on hardened shaft or you'll get a very short life out if it speaking from expensive experience.

I**Y

cutting steel and aluminum tube, extrusions and solid stock i regularly get 2000-3000 cuts per blade the record being about 7000 cuts in thin wall tubing i do not bother to sharpen as the cost is half the blade cost and only get a couple hundred more cuts best to use them and throw them in the scrap bin when done

D**Z

Lo he usado un mes y sin problemas

K**O

I seem to get the best results with the Dewalt brand name blades. I have tried having them resharpened with less success ... New always seems better. So nice to find one at a reasonable price.

Trustpilot

1 week ago

1 month ago