Customer Services

Copyright © 2025 Desertcart Holdings Limited

🎨 Elevate your woodwork game with flawless prep and finish!

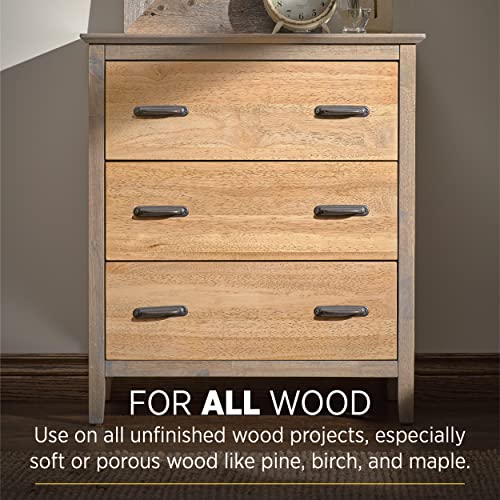

Minwax 61500444 Pre Stain Wood Conditioner is a water-based, matte-finish solution designed to prepare unfinished wood for even stain absorption. Covering up to 75 square feet per quart and drying in just 15 minutes, it ensures a smooth, professional look on birch, plywood, and other woods. Ideal for DIY enthusiasts and professionals seeking consistent, high-quality results.

| ASIN | B002OTUYCY |

| Batteries Required? | No |

| Batteries included? | No |

| Best Sellers Rank | 413,311 in DIY & Tools ( See Top 100 in DIY & Tools ) 1,157 in Stain |

| Colour | Brown |

| Coverage | 75-Square Feet |

| Customer Reviews | 4.7 4.7 out of 5 stars (1,454) |

| Date First Available | 7 Aug. 2012 |

| Finish | Matte |

| Item Package Quantity | 1 |

| Item Weight | 880 g |

| Item model number | 61500444 |

| Manufacturer | Minwax |

| Material | Water Based |

| Part number | 61500444 |

| Pattern | Solid |

| Power source type | hand_powered |

| Product Dimensions | 11 x 12.5 x 12.5 cm; 879.97 g |

| Shape | Rectangular |

| Size | 1 Quart |

| Style | Classic |

E**N

Great conditioner

Did a great job on birch plywood before stain was added

B**.

Great product

I use it as an additive to acrylic pouring medium to get special effects. Works like magic!

P**N

Worked well

The product had a very hard to remove sticker in Polish covering the instructions for use, which were crucial for safety reasons. The pre stain itself worked well.

J**B

Allow me to share my experience with wood conditioner and dispel a common misconception. Despite my dad's claim that wood conditioner is unnecessary, I can confidently say he was completely incorrect. In fact, wood conditioner has proven to be an indispensable tool, particularly when dealing with oil stains, and it offers significant cost savings in the long run. Wood conditioner is a game-changer when it comes to treating oil stains on wood surfaces. It penetrates deeply into the wood, creating a protective barrier that prevents the oil from seeping in and causing unsightly stains. By applying the conditioner before staining, the wood surface becomes more receptive to the stain, resulting in a smoother and more even application. The end result is a flawless finish that truly showcases the beauty of the wood. Furthermore, using wood conditioner can save you money on stain in the long term. By pre-treating the wood surface with conditioner, it reduces the amount of stain required for full coverage. The conditioner helps the wood absorb the stain more efficiently, ensuring that every drop of stain goes a long way. This not only stretches your stain supply but also minimizes wastage and additional expenses. In addition to its stain-saving benefits, wood conditioner also enhances the overall durability and longevity of the wood. It nourishes the fibers, moisturizes the surface, and helps prevent cracking, warping, and other forms of damage. By keeping the wood in optimal condition, you'll save money on repairs and replacements down the line. I can confidently assert that wood conditioner is far from being for "chumps." It is an essential tool for anyone looking to achieve professional-level results while tackling oil stains. Its ability to save money on stain, enhance durability, and ensure a flawless finish makes it a must-have in any woodworking or refinishing project. So, don't be swayed by misconceptions—embrace the power of wood conditioner and witness the transformative effects it has on your wood surfaces. Trust me, you won't regret it.

R**E

merci bien reçu le collie et super bien emballer..

D**É

top

M**E

For years, I never used a wood conditioner before staining—and honestly, I thought it was optional. Now that I’ve used the Minwax Pre-Stain Wood Conditioner, I’ll never go without it again. This product makes a dramatic difference in how stain is absorbed, especially on softer woods like pine or maple. It smooths out uneven absorption, prevents blotching, and gives a beautifully uniform, professional-looking finish. Applying it is easy, it dries quickly, and it truly lets the natural beauty of the wood shine through once stained. I’m so glad I started using this—it has completely elevated the quality of my woodworking projects. Highly recommended for any woodworker, beginner or experienced! Do a comparison on your next project and I believe you will become a fan of it too!

R**N

Minwax Pre-Stain is a rather interesting material. I have used it mostly on Oak, specifically Red Oak. There is some technique necessary to get good results. With that it functions very well. Here's what I've experienced; I've tried staining with and without this Pre-Stain product on the same piece of Red Oak. [NOTE WELL that Oak is extremely porous in certain areas and not so much in other areas.] Those initial experiments were quite revealing as the stain on the wood that was "Pre-Stained" was clearly more even. Case#1: I painted it on with a chip brush and let it sit for an hour before wiping off the excess and then staining. The results were less than desireable because over that time period it remained a liquid (never dried or cured) and would continually bleed to the surface where the wood tubules in the most porous areas soaked up a lot of the material. It continued to bleed to the surface for 2 days after staining. I was not happy and kept wiping off excess material that bled to the surface. Nevertheless, the stain did look OK. Even wiping off the excess 'Pre-Stain', that did not effect the Stain itself. It never did fully stop bleeding to the surface when I decided I needed to try applying the polyurethane finish. That went fine and after applying Minwax polyurethane there was no more indications of the Pre-Stain bleeding. I'd really like hear from a Minwax expert on this phenomenon. Case#2: After my first experience (Case#1) I decided that it doesn't take very long for the "Pre-Stain" to soak into the more porous areas that prevents darker staining in those more porous areas. Consequently, I applied the Pre-Stain on my next experiment and wiped off the excess material within a 5 to 10 minute time frame. Then I waited overnight before trying to stain. I re-wiped that surface several times to make sure I did not have a lot of excess Pre-Stain that could bleed up to the surface - before applying the stain. THIS TIME after staining I had no bleeding! I've attached a photo of Case# 2. This is the exposed side of a bathroom vanity that I'm building out of Red Oak. My objective was two-fold; I wanted to avoid an excessively dark stain AND I wanted to avoid the "orangy" look that you can get with 'Red Oak 215' and in particular 'Golden Oak 210B'. I've also attached the Minwax oil-based color chart. I chose the Minwax 'Early American 230'. And, to prevent an excessively dark stain I diluted it 2:1 with Minwax 'Natural 209'. The finished product came out just a little darker than I preferred but acceptable - and most important to me was no "orangy" look. Incidentally the strip on the left is the unfinished and unattached 7/8" Face Frame. The side of the vanity consists of 4 boards glued together. I am new to this whole process but thought it might be helpful to share my experience. For the record, on the project where I did experience bleeding of excess Pre-Stain, there was no adverse effects on the finished product, even though at the time it was very irritating.

Trustpilot

1 month ago

2 days ago